Environment

We established our Environmental Problem Project Team in 2002 with the goal of becoming an "Environmentally Friendly Morimura." Then, in 2007, we formulated Environmental Policy, which incorporates our founding spirit, and introduced the Environmental Management System to vigorously and systematically promote actions for protecting the global environment. We acquired ISO14001 certification, an international standard for environmental management system, in March 2008.

Taking advantage of functions only available to trading companies, we produce products and technologies that help reduce environmental impact as well as products the exert low environmental impact in production processes in Japan and overseas. We strongly supply and encourage the use of these products and technologies across society.

Environmental Policy

≫

Environmental Policy

≫

<Environmental Basic Philosophy>

MORIMURA BROS., INC. recognizes that environmental problems have become such potentially long-term-issues on global scale, and shall make every possible effort towards realizing a "sustainable development" which is aimed at creating a harmony between social and economic development, and sound environmental conservation.

<Environmental Basic Policy>

In accordance with the Environmental Basic Policy shown below, MORIMURA BROS., INC. shall endeavor to realize the Environmental Basic Philosophy through domestic and overseas business activities.

- 1.Management Philosophy

- We shall recognize the importance of environmental problems and strive to manage our business activities by balancing social and economic development, and environmental conservation.

- 2.Compliance with Environmental Laws and Regulations

- We shall comply with various relevant environmental laws and regulations, international rules, as well as all agreements signed by us.

- 3.Environmental Activities

-

1)Consideration on the Natural Environment

We shall act considering ecological and environmental protection issues and the preservation of biological diversity.2)Efficient Utilization of Resources and Energy

We shall recognize the finite nature of resources and energy, and endeavor to make its effective use.3)Contribution to the Creation of a Recycling-oriented Society

We shall contribute to create a recycling-oriented society by reducing waste, and reusing and recycling resources.4)Contribution to the Creation of a Low Carbon Society

Based on the recognition that the creation of low carbon society is an urgent issue, we shall engage actively to reduce greenhouse gas emissions.5)Contribution to Society

We shall join, support and promote activities, which contribute to the resolution of environmental problems. - 4.Environmental Management Systems

- We shall familiarize all directors and employees with this Environmental Policy and also disclose it publicly.

- 5.Education and Disclosure of Environmental Policy

- We shall familiarize all directors and employees with this Environmental Policy and also disclose it publicly.

October 1, 2007 Established

January 1, 2013 Revised

July 1, 2025 Revised

Becoming a global, environmentally friendly corporation

Becoming a global, environmentally friendly corporation

We acquired ISO14001 certification, an international standard for environmental management system, in March 2008.

We acquires ISCC PLUS Certification

We acquires ISCC PLUS Certification

ISCC PLUS ensures that certified items, such as biomass and recycled raw materials, are properly managed via the use of the mass-balance approach*2 throughout their supply chains, including manufacturing process.

MORIMURA BROS., INC. undertakes and declares to comply with the ISCC PLUS requirements in accordance with the latest ISCC regulations.

Our Initiatives

Our Initiatives

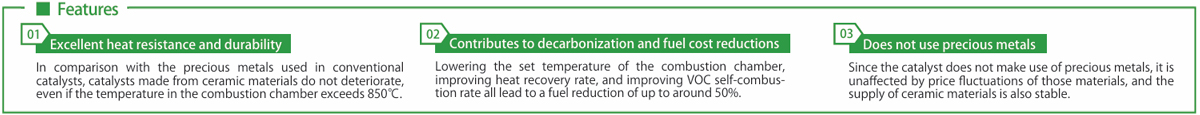

Heat-resistant ceramic catalysts for exhaust gas treatment

Hazardous substances (volatile organic compounds, VOCs) contained in exhaust gases from factories can have adverse effects on human health and the environment. As a means of disposing of these harmful substances, factories use regenerative thermal oxidizer (RTO) systems, in which they are rendered harmless by burning at high temperatures of around 800°C or higher. At the same time, there are issues such as increased fuel costs and increased CO2 emissions due to the combustion process. One solution contributing to overcoming these issues is a heat-resistant ceramic catalyst installed inside RTO systems. This catalyst uses a material developed by Murata Manufacturing Co., Ltd., that can efficiently process harmful substances. This heat-resistant ceramic catalyst is expected to reduce both VOC emissions and costs at the same time.

Zgaia™ low-temperature sintered zirconia for reduced environmental impact

Tosoh succeeded in mass-producing zirconia in the 1980s, and maintains the world's top market share in the field of fine ceramics.

In 2021, they developed the Zgaia™ series of zirconia, which can be sintered at a lower temperature (1,250°C) than conventional zirconia (1,500°C), and can therefore be expected to reduce CO2 emissions by lowering sintering temperatures.

Tosoh has also succeeded—for the first time in the world—in the development of Zgaia™ 1.5Y-HT, a low yttria (Y2O3) grade, for which it was impossible to obtain as a sintered material with conventional zirconia, achieving both high strength and a high degree of toughness. This will result in the emergence of new functions, and is expected to be used in various applications in the future.

We will continue to remain close to the development of innovative technologies and expand applications and markets for zirconia.

Utilizing wine pomace, a winemaking byproduct

Through a process of trial and error, and with the cooperation of our partner companies, we developed wine pomace extract (for flavoring applications), extracted by steam distillation of wine pomace, and have been proposing it as a product to beverage manufacturers since 2022.

When added as a flavoring, this extract has been found to enrich the flavor of wine, and enhance citrus flavors.

At the same time, it is difficult to ensure stable quality because the characteristics of the available wine pomace differ depending on the winery, grape variety, and various seasonal factors.

We will continue to make improvements, and aim for the adoption of wine pomace extract for use in both alcoholic and non-alcoholic beverages.

Magnesium Alloy Recycle Business

Magnesium alloy ingot

Magnesium alloy ingot

Producing secondaly magnesium ingot uses less energy and generates lower CO2 than primary magnesium ingot production, leading to a reduced impact on the environment. We also established a magnesium recycle plant in the Chonburi province of Thailand in 2008, which also contributes creating new employment opportunities.

Author: Japan Foreign Trade Council, Inc.

"Initiatives by trading companies to achieve the SDGs" Special seminar

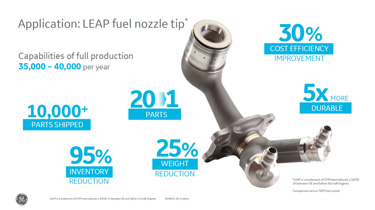

Manufacturing Innovations Using Additive Manufacturing

We sell metal powder used in 3D printers made by AP&C (Canada), a subsidiary of Colibrium Additive(Former GE Additive), in both Japan and South Korea.

The benefits of manufacturing with additive manufacturing (3D printing) are highly compatible with the SDGs.

Some examples include:

- 1) Reductions in waste material from the manufacturing process

- 2) Reductions in stock parts and local consumption of locally-produced goods

- 3) Contraction and simplification of the supply chain (reductions in costs and CO2)

- 4) Improvements and optimization of production efficiency (compatibility with DX)

- 5) Contributions to industrial and technological innovation by producing high-grade components that can only be made through additive manufacturing

Metallic materials are already on the market for the aerospace, medical, and die-cast industries and are being considered as a mass production technology for automobiles. Resin materials were greatly utilized to make up for the pandemic-induced lack of medical supplies, and initiatives to put the technology into practical use have been accelerating as a dominant technology in various fields for achieving a sustainable society.

▲A fuel nozzle for LEAP engines mass-produced by GE Aviation using additive manufacturing

Achieving a Circular Society through Use of Reclaimed Resin

We are now working to expand the market further, focusing on applications where reclaimed resin has not been utilized because of safety or other quality concerns, including detergent containers, outside air conditioning units, and washing machine pans.

Expo Booth Using the Zero CO2 System

This system was first introduced in 2022 by expo organizer JTB Communication Design. In concrete times, this system utilizes carbon offsets using green power certificates to replace the electricity used in exhibit booths with next-zero CO2 emissions.

As we have many opportunities to host booths at expos, we will continue to promote our sustainability activities, which include our contributions to the SDGs and carbon neutrality, from familiar places by utilizing this system.

- 2016/05/27

- Kyusyu Sales Office received an award for ECO-Friendly Office.

- 2016/01/06

- Participated in volunteer cleanup activity in the Kyu-Shiba Rikyu Garden.

- 2015/10/08

- Talked about our corporate approach to environmental problems on Environmental Course 2015 held by Japan Foreign Trade Council, Inc.

- 2015/10/06

- Joined ” 2015 Office Road Clean Campaign”

- 2014/08/05

- Joined ” 2014 Office Road Clean Campaign”

- 2013/08/08

- Joined ” 2013 Office Road Clean Campaign”

- 2012/08/07

- Joined “Office Road Clean Campaign”